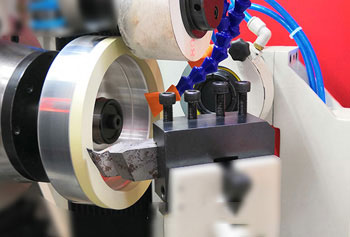

The slurry pump and the rolling mortar wall are mainly made of wear-resistant castings . Turning tools need to meet good high temperature resistance and impact resistance. ZT superhard launched ZBN300E and ZBN300 grades, which are used in the fields of high hardness cast iron and hard steel respectively, and have good user experience in Brazil, Russia, Turkey, India, Vietnam, South Africa, China and other countries. The following is a processing case:

Solid CBN Inserts For High Chromium White Cast Iron Slurry Pump

The material of the slurry pump is mainly high-chromium cast iron with a hardness of about HRC65. For heavy-duty cutting, ZT recommends that you use ZBN300E solid CBN inserts, which have stable cutting performance and high cost performance, and can effectively reduce production costs for customers.

Item: ZBN300E RNGN120400 Solid PCBN Inserts For Slurry Pump

Workpiece name: Slurry Pump

Workpiece material: High chromium white cast iron Cr26

Workpiece hardness: HRC60

Machining position: End face, Inner ring

Machining type: Heavy interrupted, rough machining

Inserts grade: ZBN300E

Insert specification: RNGN120400

Cutting type: Dry cutting

Cutting parameters:

| Inserts | Vc(m/min) | Ap | F |

| ZBN300E | 75 | 2.5 | 0.12 |

Solid CBN Inserts For High Manganese Steel Rolling Mortar Wall

Item: ZBN300 Solid CBN Inserts For Rolling Mortar Wall

Workpiece name: Rolling Mortar Wall

Workpiece material: High manganese steel

Workpiece hardness: HB240

Machining position: Inner conical surface

Machining type: Heavy interrupted, rough machining

Inserts grade: ZBN300

Insert specification: SNMN150716

Cutting type: Dry cutting

Cutting parameters:

| Inserts | Vc(m/min) | Ap | F |

| ZBN300 | 60 | 6 | 0.4 |