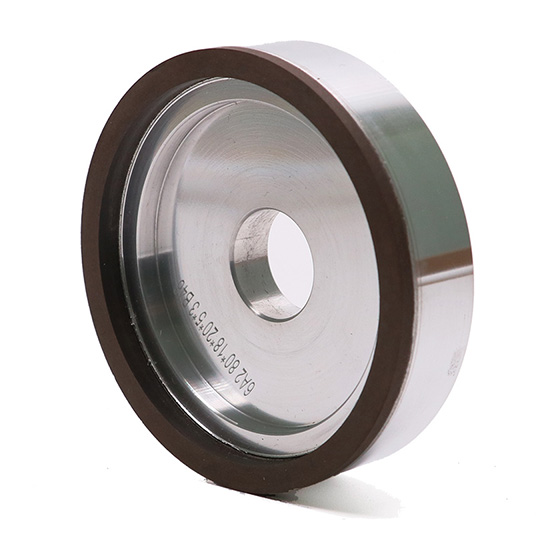

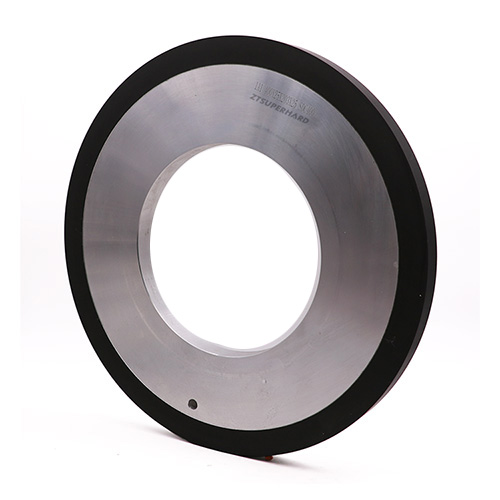

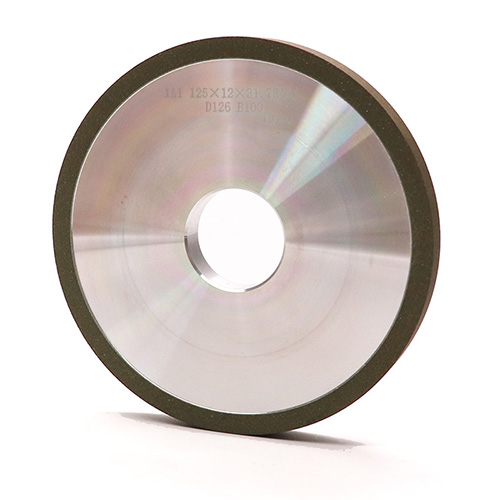

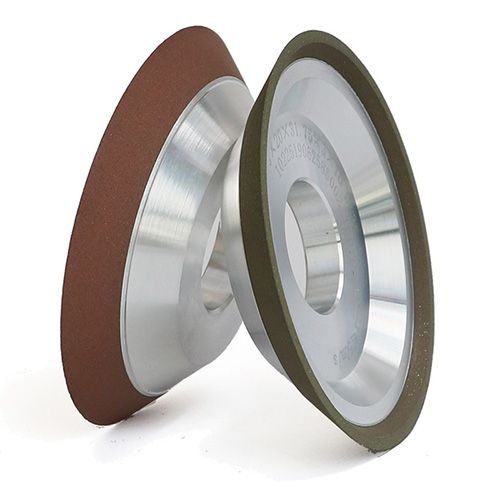

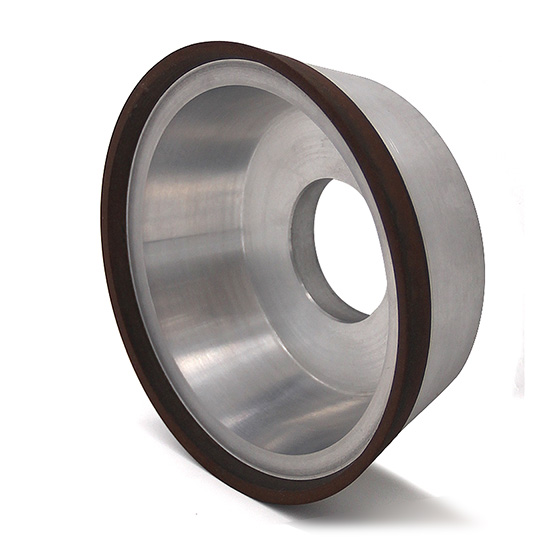

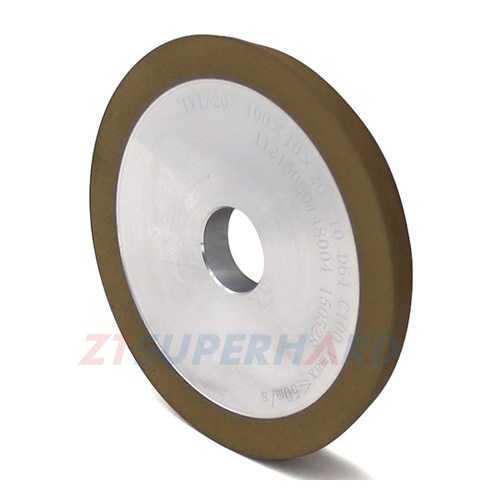

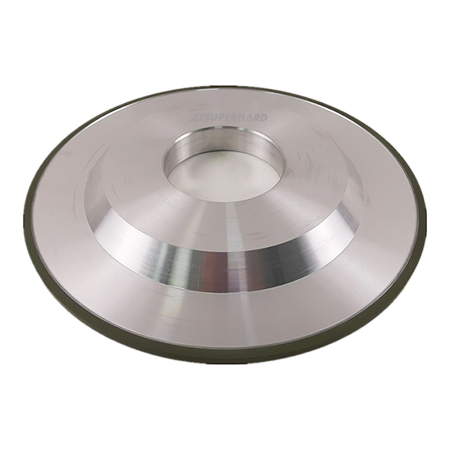

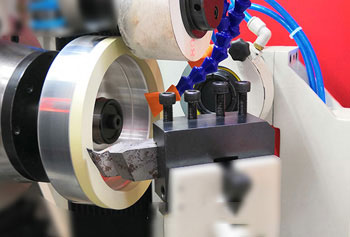

Diamond grinding wheels for Tungsten carbide have features of good self-sharpening, low heat generated during grinding, not easy to block and reduces the phenomenon of working burns during grinding. Resin bond has a certain elasticity and is conducive to improving the roughness of the work piece surface, mainly used for fine grinding, semi-fine grinding, sharpening grinding, polishing and other processes. Diamond grinding wheels are widely used in cut off grinding, External Cylindrical Grinding, Surface Grinding, Internal Cylindrical Grinding, forming grinding and other grinding processing, Can effectively save you costs and improve production efficiency.

The diameter range is 10 ~ 900mm; the thickness range is 0.5 ~ 300mm; the grit size range is 80# ~ 2000#. We can also design and make nonstandard grinding wheels according to customers' requirement.