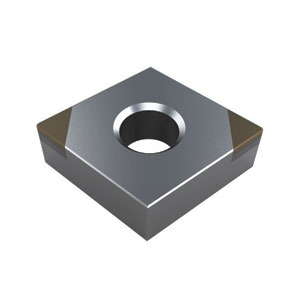

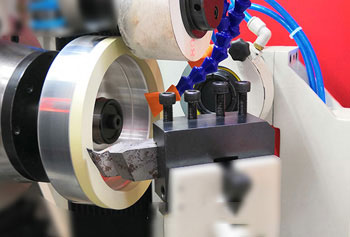

Hardened steel is to meet the use requirements of different parts, after the heat treatment of steel, rigidity, hardness, wear resistance, fatigue strength and toughness can be improved a lot, hardness can reach HRC60 above, it is difficult to process.In the process of processing the quenched steel above HRC60, the hardness of the tool itself must be higher than the hardness of the quenched steel, and this kind of quenched steel workpiece, more belong to the high precision parts, such as mold, ball screw, the surface quality requirements are higher, so the current processing of HRC60 quenched steel tool materials mainly PCBN inserts.

Hardened steel gear machining

Processing parts: face, hole

Processing procedures: finishing, boring

Advantages: ZT PCBN tool materials for continuous, slight intermittent, heavy intermittent processing of hardened steel

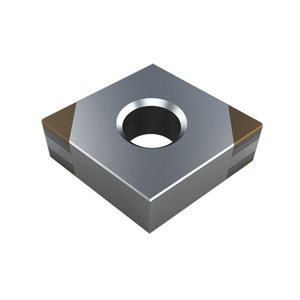

Wind power bearing

Processing parts: outer circle, face, roll

Processing procedures: continuous finishing, slight intermittent processing

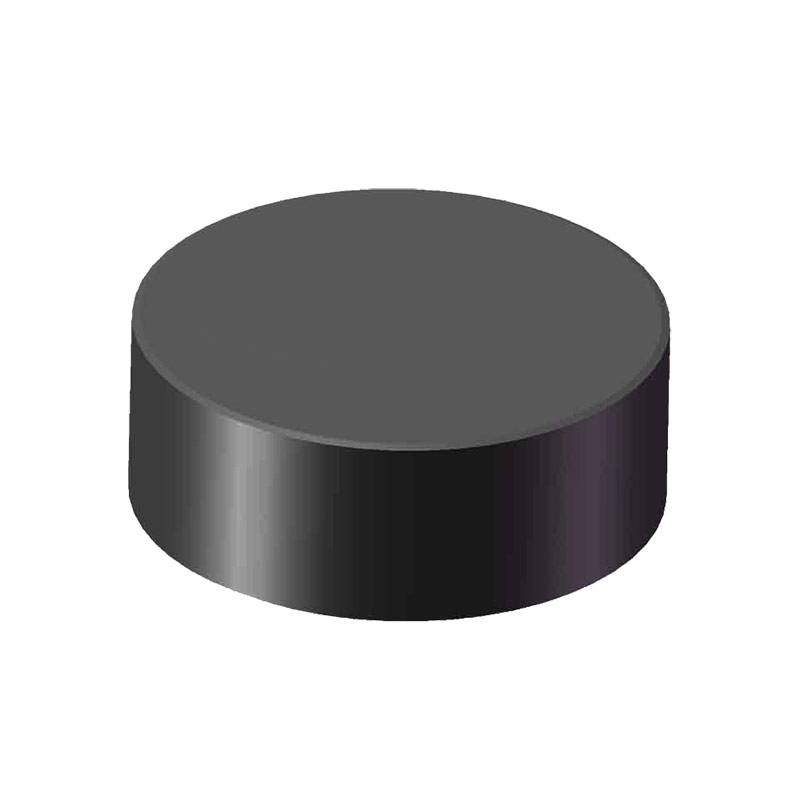

Advantages: ZT RNGN090300 PCBN inserts for continuous working condition, high precision, improve efficiency, extend tool life.RCGV120700 solid CBN inserts can meet the requirements of roller finishing and improve the processing efficiency.

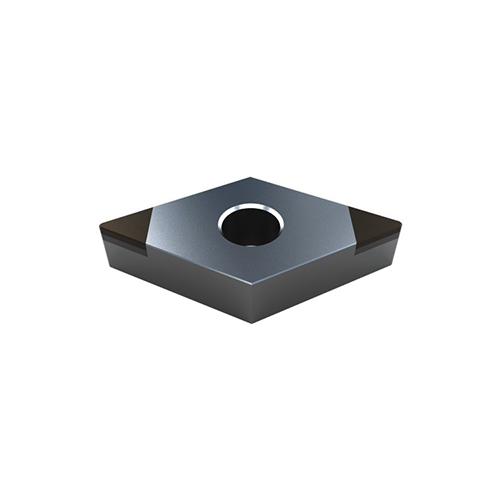

Precision machined hub bearings

Processing parts: cylindrical, boring

Processing procedures: continuous finishing, slight intermittent processing

Advantages: ZT PCBN tool for continuous working condition, high precision, improve efficiency, prolong tool life.

Common hardened steel parts include gears, bearings, wind bearings, hub bearings, gear rings, etc. Ztsuperhard are available with suitable pcbn cutting tools, For more information, please contact Alice, email: sales@ztsuperhard.com, mobile: +86 17329325308