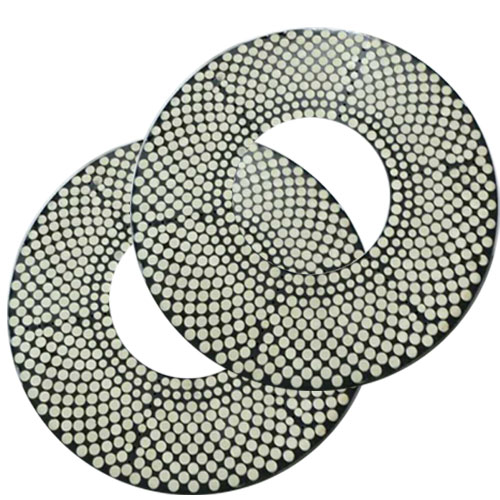

PCD is a kind of super hard tool material. It has low price. PCD material has the characteristics of high hardness, good wear resistance, large heat transfer coefficient, small friction coefficient and thermal expansion coefficient, and good strength and toughness. PCD composite based on tungsten-cobalt carbide has better strength and toughness. It is widely used in the processing and manufacturing of automobiles, airplanes, ships, building materials and sporting goods and other fields of cobalt wells and geological exploration. In recent years, more and more people start to study to use PCD for high precision machining. The durability of tools made of PCD materials is very high, usually hundreds of times than that of conventional carbide tools. Therefore, PCD is known as the ideal tool material for the 21st century. However, the superhardness and wear resistance of PCD materials also bring difficulties to the processing of materials. The most basic and easy-to-implement processing method of PCD materials during mechanical grinding is diamond grinding wheel. Therefore, deep research on the removal of workpiece materials during grinding has great significance to improve the surface quality of PCD materials and improve the sharpening quality of PCD tools. Ztsuperhard diamond grinding wheel could offer vitrified diamond grinding wheel for peripheral grinding of PCD inserts.

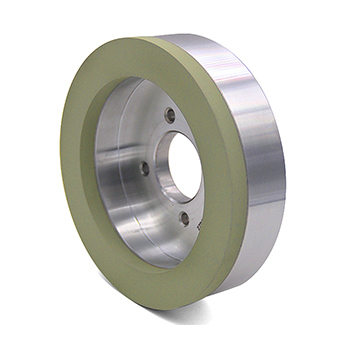

PCD grinding wheel

To achieve tool cutting of the workpiece material, the following conditions must be met. First, the knife should have higher hardness than the workpiece material. Second, the blade should be sharp with positive pressure and relative motion between the tool and the workpiece. Vitrified diamond grinding wheel can be seen as a multi-blade tool. In the grinding process, for a certain abrasive micro-blade, although the positive pressure and relative motion conditions are always satisfied, the hardness and sharpness conditions are not always. The orientation of the diamond crystals in the PCD material is random. The orientation of the diamond crystals in the PCD material is random. Due to the anisotropy of the crystal, the hardness of the crystals varies greatly in different directions. At the same time, the orientation of the diamond abrasive grains (synthetic diamond crystals) on the surface of the grinding wheel is also random, and the anisotropy of the crystals also makes the hardness of the micro-blades of the abrasive grains in the grinding direction greatly different. For a fixed abrasive grain, if the grinding direction is exactly the direction in which the crystal hardness is the highest, the hardness condition of the cutting can be satisfied. Therefore, it depends entirely on the orientation of each diamond crystal on the surface of the PCD material. When the micro-blade encounters a softer part, the condition will be satisfied. The sharpness of micro-blade is greatly related to the self-sharpening effect of the grinding wheel. The self-sharpening effect of the diamond grinding wheel is fundamentally different from the self-sharpening effect of the ordinary grinding wheel. Besides the self-sharpness of the new blade by the peeling off of the abrasive particles, more important is the cleavage and fragmentation of the abrasive particles themselves.

In the process of grinding the PCD material by diamond grinding wheel, the main removal method of PCD material is cutting, extrusion and sliding of the PCD material by the abrasive particles. The graphitization, cleavage and shedding of the diamond crystal in the PCD material can not be ignored. The instantaneous localized graphitization of the diamond crystal grinding point in the PCD material is beneficial to the material removal, but the severe graphitization phenomenon will greatly reduce the surface quality of the workpiece. The limited cooling measures should be adopted to avoid severe graphitization phenomenon. In the diamond grinding wheel, the cleavage of the diamond crystal is an important way for the self-sharpening effect of the grinding wheel. During the sharpening process of the PCD tool, the severe cleavage of the diamond crystal on the processing surface will reduce the sharpening quality of the tool, and measures should be taken to ensure to control the cleavage to a minimum. The diamond crystal on the edge of the machined surface is easy to fall off during the grinding process. When the tool is sharpened, the cutting edge is the edge of the machined surface. Therefore, the relationship between the grinding direction and the cutting edge direction should be correctly handled to avoid the falling off of diamond crystals on the edge detached by the tensile force acting surface.