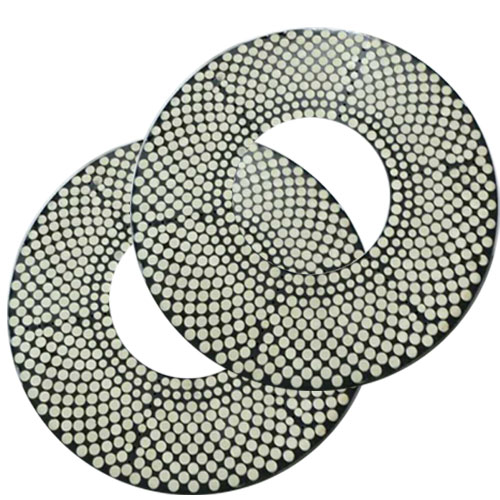

Resin bonded diamond grinding wheels for tc carbide inserts from ztsuperhard offers the perfect solution for the peripheral grinding of cutting inserts made of tungsten carbide and cermet. a range of newly developed bond systems with optimised strength and increased brittleness are used. when combined with new diamond qualities, the result is efficient grinding tools that improve the grinding process while simultaneously increasing workpiece quality.

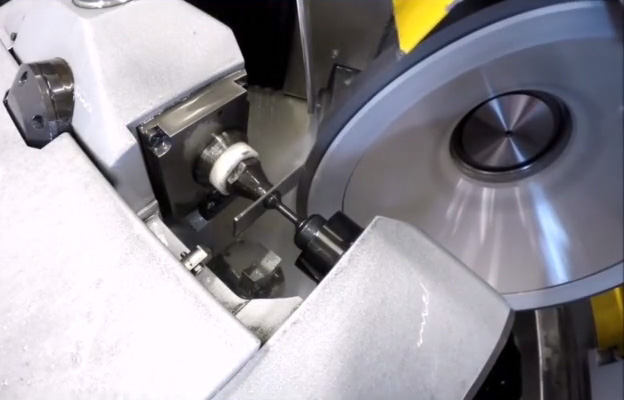

Now as for the peripheral grinding machines, the diamond grinding wheel frame not only performs high-speed rotation but also axial swing, so that the grinding wheel is generally not trimmed during the whole grinding process to avoid huge waste. However, when the new grinding wheel is mounted on the flange, there is a coaxiality error between the grinding wheel and the flange. Therefore, when new resin diamond wheel is used for the first time, the grinding wheel should be trimmed so that the grinding wheel, the flange and the main shaft could rotate on the same axis. In this way, the wheel could have the correct geometry. Since the grinding wheel is expensive and generally not trimmed, the grinding wheel should be ensured uniform wear throughout the whole use process. Therefore, the grinding wheel should be fixed in the same position at the stop position of each grinding stage. In order to achieve this, a travel switch can be installed on the left side of the grinding wheel. As long as the grinding is in place, the axial swing of the grinding wheel can be stopped at the same position. The grinding pressure not only affects the self-sharpness of the grinding wheel, also affects the wear of the grinding wheel. When the grinding pressure is insufficient, the grinding rate will be quickly reduced in the grinding process, and the surface of the grinding wheel will be polished or blocked. We can see diamond particles will be dull under the magnifying glass. When the grinding pressure is too large, the grinding wheel will be quickly worn during the grinding process, the diamond particles will be broken from the bond, and the diamond particles will fall off. At this time, obvious luminous sparks appear, and the grinding wheel will vibrate or it will be blocked. When the grinding pressure is correct, the grinding process will be good at the optimum feed rate, and the alloy removal rate will remain the same. At this time, sharp diamond grains will fully be expanded on the surface of the grinding wheel. After testing, the influence of grinding pressure includes the following factors, namely, the transverse feed rate, the diamond concentration, the size of the indirect contact area of the grinding wheel and the workpiece, and the effective duration of the individual diamond particles, diamond particle size and shape, bond type and hardness.

During the grinding process, the grinding heat is generated due to the grinding force. The grinding wheel consists of two parts. The matrix is generally an aluminum alloy and the diamond layer has large thermal conductivity. Under the action of grinding heat, the entire grinding wheel expands rapidly, and the size of the grinding wheel in the diameter direction increases a lot. When the resin diamond wheel is used to grind the cemented carbide insert, the wear of the grinding wheel changes substantially in a straight line. However, after grinding for a period of time, due to the elastic retraction of the grinding system, the grinding wheel wears less and then enters the normal grinding. Grinding wheel wear is related to grinding force and grinding heat. In normal pressure grinding, the wear of the grinding wheel is basically uniform.